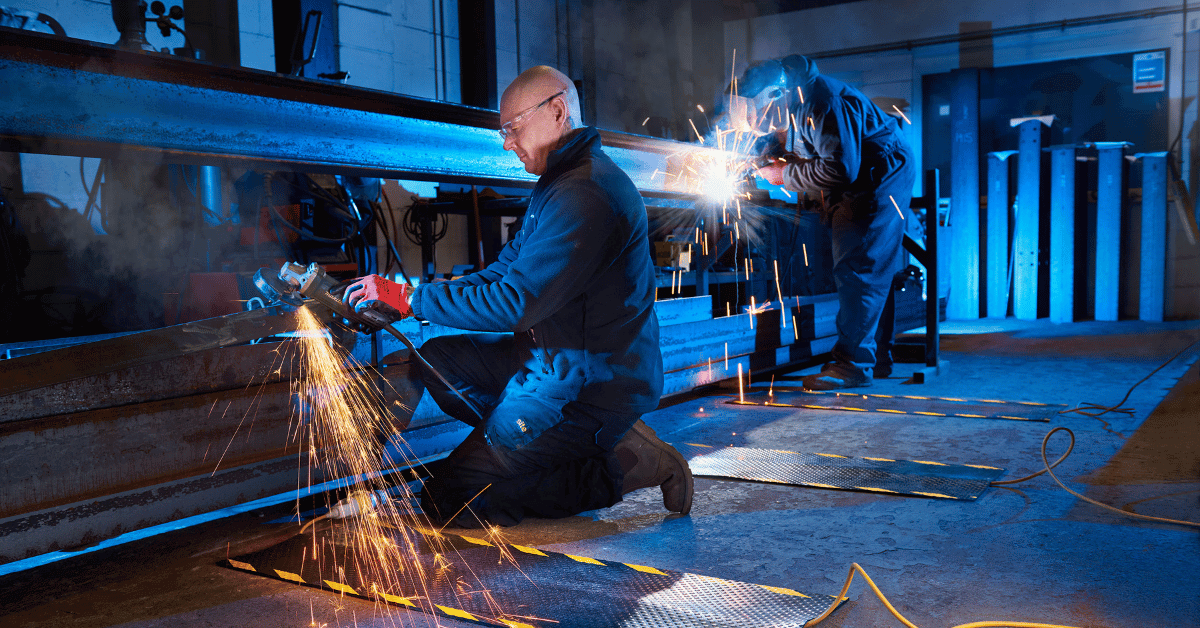

At ASH Integrated Services, we’ve taken control of this crucial part of the M&E process by bringing fabrication in-house.

The result?

Faster delivery, higher quality, and greater flexibility for our clients.

When it comes to delivering complex mechanical and electrical (M&E) projects, every detail matters.

From pipework to cable supports, the components behind the scenes determine how smoothly a project runs.

Fabrication That Works for You

Our dedicated fabrication team produces custom components that directly support our M&E operations.

When we build the parts ourselves, we precision-engineer each one to meet your project’s exact needs.

That might mean:

- Bracketry and support systems for electrical and mechanical installations.

- Pre-fabricated pipework assemblies for heating, hot water, or chilled systems.

- Cable containment solutions like tray work, trunking, and riser supports.

- Mild and stainless-steel components for plant rooms.

- Frameworks and enclosures for solar PV or battery storage.

- Custom ductwork and ventilation structures.

If it saves time on site, improves efficiency, or meets a bespoke requirement, we’ll fabricate it.

The Advantages of In-House Fabrication

Choosing a contractor with in-house fabrication gives clients several clear benefits:

- Reduced site time – Prefabricated assemblies mean faster installation, less disruption, and fewer delays.

- Consistent quality – Every piece is produced under our supervision, giving complete control over standards.

- Agility – If designs change or challenges arise, we can adapt quickly without waiting on external suppliers.

- Tailored solutions – Each component is made to suit your specific building or system.

- Sustainability – By fabricating to measure, we minimise waste and support greener project delivery.

Part of the ASH End-to-End Service

With over 60 skilled engineers supported by a full project management team, fabrication is one more way we strengthen our promise to be a true single-point provider.

From design to installation and ongoing maintenance, we keep every stage of your project under one roof.

That means less stress for you, and more confidence that the work will be done right, first time.

Why It Matters

In-house fabrication is about giving clients the peace of mind that comes with complete control, seamless coordination, and bespoke solutions.

By choosing ASH Integrated Services, you’re choosing a partner that has everything covered, from the first drawing to the final fix.

👉 Ready to see how our in-house fabrication can make your project smoother, faster, and more efficient?